Special Reports & Feature Stories!

|

||||||||||||||||||||||||||||||

|

ISOLATOR INSTALLATION, INSPECTION, AND SERVICE! SOME DO’s AND DON’T’s In the last twenty (or so) years, I’ve been privileged to have been able to watch the tremendous advances in technology that continues to inspire several manufacturers around the world to explore new developments in electronic life safety systems. Unfortunately, each new advance exposes some vulnerability that must also be addressed. In this article, we’re going to discuss “isolators” and more specifically, the correct wiring methods for the various types of circuits you’re going to encounter, as well as the testing that must be performed, both at the system’s commissioning/Verification and on an annual basis. We’re going to focus on the changes currently adopted by the Canadian Standard for Installation of Fire Alarm Systems (CAN/ULC-S524) as well as what’s “in the pipe” in the way of amendments.

ISOLATOR TYPES AND TERMINOLOGY What is an isolator, and how does it work? Let’s begin by actually answering these two questions. An isolator is a device that is designed to limit the extent a circuit is compromised by a single “short” fault. In North America, there are four distinct “families” of short circuit isolators. They are:

Most isolators are “dumb” devices comprising a simple relay in a short sensing circuit on their “out” terminals. As long as there is resistance on the circuit, they’re “happy”. When the resistance drops to nothing (a short), they activate to preserve the loop integrity on their “in” side. Some manufacturers have chosen to make their isolators “smart” by employing their panel’s protocols to “communicate” with each isolator. This has the advantage of being able to “group bypass” an entire floor area from the common control if work is being performed there, without affecting the operational status of the rest of the system. You’ll usually find these isolators employed by companies that are engaged in providing large scale networked type fire alarm systems (for the obvious reason that it also makes testing easier).

APPLICABLE CODES AND STANDARDS NBC 2015, VBBL 2019 The only time isolators are actually mentioned in any Canadian Building Code is in conjunction with in-suite signalling means. This is articulated in BCBC 2018 (as adopted from NBC 2015) in Section 3.2.4.19 called Audibility of Alarm Signals and reads in sentence (8): “Audible signal devices within a dwelling unit or a suite of residential or care occupancy shall be connected to the fire alarm system: a) in a manner such that a single open circuit at one device will not impair the operation of other audible signal devices on that same circuit that serve the other dwelling units or suites of residential or care occupancy, or b) on separate signal circuits that are not connected to the devices in any other dwelling unit, public corridor or suite of residential or care occupancy. (See Appendix A.)” The City of Vancouver has improved upon this requirement by adding “short circuit” to their VBBL 2009 Clause 3.2.4.19(8)(a). Why? Because the former City Electrician there (Arkady Tsisserev) was a Professional Electrical ENGINEER and considered this to be “Best Practice”. This has been carried forward through successive Bylaws essentially unchanged. In the City of Vancouver, not only do you have to wire suite signaling appliances in a Class “A” loop, you have to also provide isolators, unless of course, you’re using separate signal circuits for each dwelling unit. CAN/ULC-S524-14 |

|

|||||||||||||||||||||||||||||

|

We’ve provided links to diagrams at the bottom of this page which detail both Class “A” interconnected field devices and a Class “A” Riser interconnected to field devices in a Class “B” configuration as part of this article. This is one area where the manufacturer’s installation instructions also fall short and may even reference practices only acceptable outside of Canada (i.e. NFPA requirements). The essential difference between the drawings you’ll see in the official amendment to the Standard and ours centres around one additional isolator which we’re suggesting be added to the “return” side of the loop to protect this part of the riser if you are employing uni-directional isolators. In this instance, I’m of the opinion that this qualifies as an improvement on the actual requirements of the Standard (something that’s referred to as “good engineering practice”). There are currently two versions of CAN/ULC-S524-14. One includes the Amendments published in January of 2016 as a separate insert while the other will not have an amendment. Please ensure your Standard includes the statement: “Including Amendment 1” on the cover. So, let’s begin with Clause 5.7.3: “Where a data communication link utilizing active field devices or supporting field devices serves more than one National Building Code of Canada required fire alarm zone, a fault within one National Building Code of Canada Required fire alarm zone shall not prevent the normal operation of other input or output field devices in another National Building Code of Canada required fire alarm zone, except as noted in Clause 5.7.3.4. Note: See also Clause 4.3.1.8 and 4.3.1.9.” 5.7.3.4 states: “Active field devices or supporting field devices serving water flow devices, supervisory devices on sprinkler systems, or duct type smoke detectors on HVAC systems that are located within a National Building Code of Canada required fire alarm zone but serve other National Building Code of Canada required fire alarm zones, need not be separately fault isolated from each other or the National Buiilding Code of Canada required fire alarm zone.” 5.7.3.5 states: “A control unit or transponder or its associated data communication link that serves more than one floor area, shall be subject to the constraints of Clause 5.7.3.1.” 5.7.3.6 states: “Data communication link style A with fault isolation modules, or data communication link style C with fault isolation modules, or an equivalent method shall be utilized to meet the requirements of Clauses 5.7.3.1, 5.7.3.4, and 5.7.3.5. (Refer to Figure 5).”

Section 4.3 is entitled “ELECTRICAL SUPERVISION”. 4.3.1.8 states: “Except as permitted by Clause 4.3.1.10 or Clause 4.3.1.11, where a power buss circuit serves more than one National Building Code of Canada required fire alarm zone, a single fault (open circuit fault, short circuit fault or ground fault) shall not prevent the normal operation of input or output field devices in more than one National Building Code of Canada required fire alarm zone. NOTE: Refer to Appendix A (Informative) Explanatory Materials, Clause A4.3.1.8.” 4.3.1.9 states: “Except as permitted in Clause 4.3.1.10, where an audio buss serves more than one National Building Code of Canada required fire alarm zone, a single fault (open circuit fault, short circuit fault, or ground fault) shall not prevent teh normal operation of input or output field devices in more than one National Building Code of Canada required fire alarm zone.” 4.3.1.11 states: “Where a power buss serves supporting field devices which are located within a common National Building Code of Canada required fire alarm zone but serve other National Building Code of Canada required fire alarm zones, the power buss segment serving these supporting devices is not required to comply with Clause 4.3.1.8.” 4.3.1.12 states: “Class A circuit with fault isolators installed in accordance with Subsection 10.2, Fault Isolators, or an equivalent method, shall be utilized to meet the requirements of Clauses 4.3.1.9 and 4.3.1.10. NOTE: For Data Communication Links, refer to Subsection 5.7.3, Field Device Data Communication Link.” Section 10.2 is entitled “FAULT ISOLATORS” 10.2.1.1 states: “This Subsection applies to the installation of fault isolation modules as required by Subsection 5.7.3, Field Device Data Communication Link, for data communication links between field devices. (Refer to Figures 33.1, 33.2, 33.3, and 33.4.) Note: Where available, data fault isolators should be located in a fire separated electrical room.” 10.2.1.2 states: “Data fault isolators shall be utilized when entering and leaving each National Building Code of Canada required fire alarm zone. See also Appendix A (Informative) Explanatory Materials, Clause A4.3.1.8.” 10.2.1.3 states: “Data fault isolators required by Clause 10.2.1.2 are not required between field devices located within the same floor area that are monitoring mechanical equipment serving other floor areas. NOTE: For example, water flow devices on sprinkler systems or duct type smoke detectors on HVAC systems serving other floor areas are considered part of the same area specified in Clause 10.2.1.2 and need not be separately fault isolated from other devices within that area.” 10.2.1.4 states: “Except as noted in Clause 10j.2.1.5, data fault isolators, shall be located in a separate enclosure and installed so as to be visible and accessible at all times.” 10.2.1.5 states: “Data fault isolators that are integral to a field device shall be mounted in accordance with the requirements of that field device.” Note: Field devices incorporating fault isolation modules complying with Clause 10.2.1.2 do not require additional dedicated data fault isolators.” 10.2.1.6 states: “Where a fire separation is provided, data fault isolators required by Clause 10.2.1.2 shall be installed on each side of that fire separation.” 10.2.1.7 states: “Data fault isolators installed on opposite sides of the same fire separation shall be offset horizontally to a minimum of 400 mm, and not located within the same stud space.” 10.2.1.8 states: “Where no fire separation is provided between each National Building Code of Canada required fire alarm zone, a single fault isolation module shall be utilized when isolating zones within the same floor area. Note: This Clause would be applicable to large horizontal buildings, e.g., warehouses, shopping malls, factories, etc.” 10.2.1.9 states: “Data fault isolators serving a single field device in an exit or vertical service space shall be installed on the floor area side. Note: Fault isolation modules are not required on the exit or vertical service space side. See Figure 2.4” 10.2.1.10 states: “Data fault isolators shall have an identifying mark or label on the cover plate or field device. The identifier shall be visible after installation. Where field devices incorporating fault isolation modules are used to comply with Clause 10.2.1.2, the first field device entering and the last field device leaving each National Building Code of Canada required fire alarm zone shall be marked.”

INTERPRETATION & INSTALLATION REQUIREMENTS What is a Style “A” Loop? What is a Style “B” Loop? What is a Style “C” Loop? First off, don’t get confused between “Class” and “Style”! “Style” refers to the functionality of communications loops between Listed control panels, transponders, and field devices (provided to the loop controller through a combination of the system’s firmware or software and strategically placed isolators). “Class” refers to the wiring scheme used to interconnect them. A Style “A” and Style “C” loop are actually wired identically in a Class “A” scheme. Both Style “A” and Style “C” loops have an independent return path which becomes an alternate means of communicating with connected control units, transponders and field devices should a portion of the loop become compromised by an “open” on the circuit. Style “C” loops however, provide a higher level of functionality when the loop becomes compromised by a short circuit on the wiring. A Style “C” loop is a continuous Class “A” type circuit that goes from one floor area to another without interruption. A Style “A” loop is limited to one floor area (and doesn’t usually require isolators as it’s powered by a dedicated loop controller). In a Style “B” loop, an “open” (or short) will sever communications with any control unit (or transponder) wired in the shorted circuit. Field devices are wired either Class “A” or Class “B” in a floor area. To add to the confusion, you can also “T” tap within the same floor area when you’re using addressable field devices or route both the return and primary loops into a single five conductor cable assembly in certain circumstances which are illustrated within the Installation Standard. Table 1 in CAN/ULC-S524-14 serves to illustrate the various pros and cons of the different “Styles” utilized in the communications between control panels and transponders (it also provides the means for the Verifier to identify whether-or-not the correct response occurs when a short is imposed on the communications loop between control panels and transponders). A Style “B” type loop is NOT ALLOWED in Canada for a DCL riser between control units or transponders, but it IS ALLOWED between buildings in a Campus Style Network. Class “B” wiring is NOT ALLOWED for a DCL or a Power Buss common riser between a control unit and connected active (or supporting) field devices. CLASS “A” CONNECTED FIELD DEVICES: In order for isolators to work properly in this type of configuration, the “out” side of the first unit on the floor area must face the “out” side of the last unit on the floor area. An exception exists for isolators that may employ bi-directional communication protocols. You should definitely check the manufacturer’s information and installation guide. Either way, if they identify an “in” and an “out”, you can’t go wrong. A short anywhere on the floor will result in both isolators activating which limits the loss of data/power to only the devices in that single area. This having been said, it must be noted that isolators employed on a DCL “A” loop will only have a single wire connected under each terminal, positive “in”, negative “in”, positive “out” and negative “out”. This photograph depicts an isolator terminated in a DCL “A” loop that’s wired incorrectly.

You will note that, in both our wiring circuit diagrams, there is an additional isolator added to the mix, which the diagram in the 2014 version of the Installation Standard does not include. This unit protects the return side riser between the common control and the last floor area. Please note that if the control panel’s DCL/PBR loop is equipped with on-board isolators, the first two units immediately shown in line from the common control (which we’ve highlighted in RED) are not required. Please ensure that the control panel’s documentation clearly identifies that the DCL/PBR loop is isolated (and indicates the configuration)! An exception to this rule exists where the manufacture may RECOMMEND the installation of isolators in this location as a means of preserving the integrity of the loop controller over the life of the fire alarm system. Class “A” DCL/PBR loop wiring diagram (both Style “A” and Style “C” loops are illustrated) CLASS “A” LOOP RISER WITH CLASS “B” CONNECTED FIELD DEVICES: In order for isolators in this configuration to operate as intended, both “out” sides of the two isolators installed in the floor area are “T” tapped to the Class “B” wired devices on the floor. There is an additional wiring method which is perfectly suited to a control panel replacement within a building where a traditional conventionally zoned fire alarm system was installed. Both methods are illustrated in the diagram posted to this link.

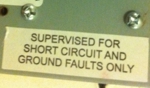

TESTING/SERVICE The testing methods vary slightly depending upon the type of isolator (as well as who manufactured it). It’s a good idea to have the installation instructions handy for the model of isolator you’re testing. This will usually include a recommended test procedure that might differ slightly from what you read here. NOTE: The manufacturer’s sugggested test methods should be used in EVERY case. SLC (Signalling Line Circuit) or DCL (Data Communication Line) Isolators: Testing method - There are two termination points on every isolator. One is an “in” from the common data loop and the other is an “out” to the field devices it serves. Short the “out” side to ensure the unit functions correctly (yes, this means that you will have to remove the cover on each unit!). Depending on the number of devices on the “out” side, you should see a string of error messages on the common control that are most commonly identified by the phrases “missing device” or “device error”, or “data loop short”. Maintain the short until you have scrolled through and noted each device that fails to report. Part of your “test” ensures that the total number of devices for each isolator does not exceed the manufacturer’s maximum limit. If more than one floor area’s devices fail to report while the short is in place you will have to note this as a deficiency on your report! If the isolator you’re testing happens to be bi-directional proceed to short the “in” side. Maintain the short until your helper has scrolled through and noted each device that fails to report. The other part of the test (with the short still in place) requires you to proceed to another floor area and initiate an alarm from there. Field devices which employ isolator bases must also be tested. If the system you’re testing employs these units (it’s usually the first smoke detector on the loop), you’ll have to find an addressable device (a manual station is usually the easiest to access) downstream of the isolator. Drop it and short the loop terminals from here. Maintain the short and have your helper scroll through and note each device that fails to report. Again, you’ll have to perform the alarm test component from a field device located outside of the shorted zone. Power Supply & Audio Riser Buss Isolators: Testing method - While shorting a power supply (or audio output circuit) is not normally recommended, opening the circuit on the “out” side of the isolator will identify the devices it protects. You must ensure the maximum current for the unit is not exceeded (or the recommended maximum number of devices). Use your meter (set to “amps”) to determine what each isolator is handling. In EVERY case, follow the manufacturer’s suggested test methods and note the results in your report. Suite Signal (Bell/Buzzer Circuit) Isolators: Normally these units are installed in the common area corridor outside of the suites they serve. They’re always located behind a suitable cover which identifies them as a fire signalling component or fire alarm device. There are two “flavours” available: “supervised” and “unsupervised”, The unsupervised isolator is NOT allowed by Code or the installation standard (CAN/ULC-S524) despite the fact that the devices may be ULC Listed! If you come across one (they will have a label affixed to them identifying them as such), you must fail the unit. No further testing is required. This is a label on an Caution! Use of ANY unsupervised Testing method - There are two phases to the required testing. One is performed while the system is in normal supervisory mode, the other is performed while the system’s sounders are active. For these tests, it is recommended they be performed inside the suite the unit serves. You will notice that there are two “outputs” on each isolator (it serves two separate suites or units). All in-suite devices controlled by an isolator are wired in a Class “A” loop. Step 1 - Remove the cover from the isolator to expose the wiring terminals. If all of the above tests are completed satisfactorily, you can move on to the next suite on the floor (after reinstalling the buzzer that is!). NOTE: If, in step 8, none of the buzzers in the suites sound, then the notification appliance circuit is programmed incorrectly! You must ensure this is corrected before proceeding with the testing of the rest of the insuite appliances. Some systems utilize a jumper setting to activate the signals if isolators are on the circuit. Other systems require access to the physical panel programming to enable this feature.

|

||||||||||||||||||||||||||||||

The Fire Technicians Network

+1 (888) 340-3473

“We are not a professional union, but together, we are a union of professionals!”

What we’re all about!

We are not affiliated with ASTTBC, CFAA, CANASA, NFPA, NAFED, or NICET (although we encourage you to explore and objectively evaluate the benefits associated with supporting their individual efforts). Membership in the Fire Technicians Network is entirely voluntary. Are you up to the challenge of demonstrating your commitment to public safety and the highest standard of professional practice?

Copyright © 2007 - 2021 The Fire Technicians Network. All Rights Reserved