TECH Q & A (FAQ’s)

|

|

||||||||||||||||||||||||||||||||||||||||||

|

“I drive alone. I inspect alone. Sometimes I even have sex alone. IMPORTANT: LINK CHANGES FOR CITY OF VANCOUVER WEBSITE The City of Vancouver’s website has recently undergone a major upgrade. Many links to Bulletins from our website will, as a result, now display a custom error page. If you happen to come across this, simply type former. (the dot is important) ahead of vancouver in your browser’s address bar, and it should open the proper document. We’ll endeavour to update all of our links once the City’s Web-Minions get finished with fixing all of theirs! We are in the process of updating our FAQ to ensure any references to the testing Standard includes both the 2004 and 2013 published editions. Please be patient!

As you navigate through the various FAQ pages on our site, you’ll notice that we’ve provided handy pointers that highlight information which might be of special interest in the answers we’ve provided. Look for these symbols in the right hand margin:

|

|

||||||||||||||||||||||||||||||||||||||||||

|

FIRE ALARM TESTING: What does a smoke detector sensitivity report look like? Can a buildings’ maintenance personnel conduct fire alarm testing in accordance with the Standards? What’s the cost for a typical fire alarm inspection? What percentage of fire alarm devices in a building are inspected annually? In which edition of CAN/ULC-S536 did it become mandatory to test end-of-line resistors? Is an inspection of the fire alarm control panel required by the Standard? How do you test a sprinkler flow switch (or alarm pressure switch)? |

|||||||||||||||||||||||||||||||||||||||||||

|

Are you required to list each device during a fire alarm system annual inspection?How many turns of a sprinkler isolation valve are required before a supervisory condition has to be annunciated at the fire alarm control panel? How much notice is required when performing a fire alarm inspection in a residential suite? Is it against Code to test heat detectors with a torch in British Columbia? How often do fire alarm devices in elevator shafts require testing (in Canada)? Can a fire alarm technician test a fire sprinkler system? Is a sound level pressure test required on an annual basis by CAN/ULC-S536? How do you test fire alarm isolator modules? Can a supervisory sprinkler device be on the same zone or initiating circuit as a flow switch? How do you test for ground fault indication when doing an annual fire alarm inspection? Will starting my pressurization fans set off my fire alarm? Who can legally perform an annual fire alarm test to CAN/ULC-S536-04(-13)? What conditions must be met when performing testing on a fire alarm system that is monitored? What does the term status change confirmation mean when testing smoke detectors? When did CAN/ULC-S536-04(-13) actually come into effect? What procedure should I follow if the FAS I’m testing doesn’t comply with the installation standard? What's the difference between a supervisory alarm and a trouble signal? How often must a fire alarm system be tested in Canada? How do you test conventional fixed temperature heat detectors? |

|||||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||

|

Can a supervisory sprinkler device be on the same zone or initiating circuit as a flow switch? Yes and no. On many older systems (typically installed before 1992) it was common practice to tie in the flow switch to the sprinkler valve that controlled the zone the switch monitored. In this instance, movement of the valve handle results in a local non-latching "trouble" on the fire alarm control. You will come across many such installations. Your testing of the circuit's operation must ensure that the alarm generated by the flow switch has priority over the trouble indication that the sprinkler valve will cause when it's moved from its normal position. To do this, partially close the valve and ensure a "trouble" condition annunciates, then initiate your standard flow test. Modern building codes require a separate latching supervisory signal manifest on the fire alarm control for any "off normal" condition of a sprinkler valve. This is often easily achieved when an addressable alarm system is employed. In this instance, it's easy to add as many supervisory initiating modules as may be required to meet the design criteria or that of the local AHJ (a conventionally wired alarm system will require a wire pair home run to the common control for each valve or device). |

|

||||||||||||||||||||||||||||||||||||||||||

|

How do you test for ground fault indication when doing an annual fire alarm inspection? In Canada, ground fault testing is usually performed at two locations. On a conventionally wired system, you have to short both sides of each initiating and indicating (NAC) circuit to ground. On an addressable system, you have to short both sides of the SLC (or addressable loop) to ground as well as any conventionally wired NAC's. The same test must be performed at each end-of-line device. |

|

||||||||||||||||||||||||||||||||||||||||||

|

What is the relevant section of the BC Fire Code that deals with the maintenance and testing of fire alarm systems? That would be in Division B - Part 6, specifically 6.3.1.2 which is entitled “Inspection and Testing”: “1) Fire alarm systems shall be inspected and tested in conformance with CAN/ULC-S536, ‘Inspection and Testing of Fire Alarm Systems’. 2) Fire alarm and detection system components shall be accessible for purposes of inspection or maintenance.” The last sentence speaks to the requirement that all devices in the building must be accessible (this includes suites in a residential structure). |

|

||||||||||||||||||||||||||||||||||||||||||

|

Will starting my pressurization fans set off my fire alarm? In most buildings which employ these types of fans, an "off normal" condition (ie. fan running) will result in a "trouble" indication at the fire alarm panel. The normal operation of exhaust fans shouldn't affect the panel, but moving any associated controller switch to the "run" or "off" position will result in a system "trouble". An alarm condition may be precipitated if the area in which the pressurization fan outlet is close to a system smoke detector and excessive dirt or dust gets blown around. It's probably a good idea to contact the monitoring station and alert the building's occupants before conducting any kind of testing involving the fire alarm system. |

|

||||||||||||||||||||||||||||||||||||||||||

|

Who can legally perform an annual fire alarm test to CAN/ULC-S536-04(-13)? For the definitive answer to this question, let's start by referencing the Standard itself, which states: “APPENDIX A (INFORMATIVE) - QUALIFIED PERSONNEL A1 Any person who performs the annual test and inspection of a fire alarm system should be knowledgeable about this Standard and have received suitable formal training or sufficient experience acceptable to the authority having jurisdiction.” There's that phrase again (it's also found in the CAN/ULC-S537-04 Verification Standard): “suitable formal training or sufficient experience acceptable to the authority having jurisdiction”. Notice what it doesn't say. It doesn't say you have to be a CFAA Certified or an ASTTBC Registered Technician. It also doesn’t say that you have to be in the employ of the system’s manufacturer (and/or be “factory trained”). The Standard leaves the final “say” to the local AHJ. In several Provinces and Territories in Canada, these individuals are often not in a position to properly evaluate a technician's capabilities or skill set. A suitable yard stick has been found in the certification and training requirements established by the two aforementioned professional associations. My best answer: Contact your local Authority Having Jurisdiction and request their qualification criteria. |

|

||||||||||||||||||||||||||||||||||||||||||

|

What conditions must be met when performing testing on a fire alarm system that is monitored? You can reference page two of the fire alarm annual test report and page 12 of the fire alarm verification report here. You can find a detailed explanation of the functional testing which SHOULD be performed on the communicator here. |

|

||||||||||||||||||||||||||||||||||||||||||

|

What does the phrase "status change confirmation" mean when testing smoke detectors? Many modern fire alarm systems are capable of employing something called "alarm verification". When enabled, this feature allows the fire alarm circuitry (or software) to discriminate between a high ambient particulate presence and actual "smoke". This can be accomplished in a number of ways, but most commonly by having two smoke detectors in the same area "alarm" within a specific time (or sequence). If only one does, the panel may actually indicate this condition by initiating a supervisory or "monitor" signal which will change to an alarm condition when the second alarm event threshold is sensed. Appendix "F" (Informative) of CAN/ULC-S537-04 states: “F1 Status change confirmation should be installed only under the following conditions: A The reduction of false alarms from smoke detectors generating spurious alarms. Such false alarms should be documented for submittal to the authority having jurisdiction as may be required; B The area being protected by the smoke detectors subject to the confirmation contains a "light" fire load and any combustion would be expected to produce a "slow rate of burn"; C Only smoke detectors should be subject to alarm confirmation. If other initiating devices are present on the same wiring circuit or zone as smoke detectors, the circuit should be arranged to override the confirmation function and provide an immediate alarm; and D The application of the status change confirmation circuit is accepted by the authority having jurisdiction.” |

|

||||||||||||||||||||||||||||||||||||||||||

|

I'm testing a building with System Sensor C2W-BA smoke detectors installed. Does observation of the LED flash pattern and comparing it to the table in the installation instructions constitute "Sensitivity Testing" as defined in the Standard? Yes. Section 5.7.4.1.6 of CAN/ULC-S536-04 (5.4.1.6 of CAN/ULC-S537-04) states: “Acceptable methods of determining the smoke detector sensitivity are: A) Manufacturer's recommended test instrument, equipment, or method;...” The key word in this sentence is method. |

|

||||||||||||||||||||||||||||||||||||||||||

|

When did CAN/ULC-S537-13 (Canadian Fire Alarm Verification Standard) or CAN/ULC-S536-13 (Canadian Inspection Standard for Fire Alarm Systems) actually come into effect? The latest of ANY Standard comes "into effect" with the publication of the newest Code release. In British Columbia, both the BC Building Code and the BC Fire Code were substantially amended in 2018. This would make the "13" edition of CAN/ULC-S537 (CAN/ULC-S536) the one to go on. The Installation Standard is the "14" version of CAN/ULC-S524 the one that's most likely referenced. In most cases, the fire alarm will have gone through a design process which always requires the involvement of a Professional Engineer who will ultimately determine which Installation Standard the proposed system (or upgrade) will follow. You should check with the local Authority Having Jurisdiction to see which version of this particular Standard they're going to be referencing. UPDATE: Ontario has formally adopted NBCC 2010 into their Building Code and NFC 2010 into their Fire Code for 2014. The former now references CAN/ULC-S524-06 (Standard for Installation of Fire Alarm Systems). UPDATE: December 10, 2018 marked the date that British Columbia formally adopted the British Columbia Building Code 2018. All fire alarm system installations must now meet CAN/ULC-S524-14 (including Amendment 1) Standard for Installation of Fire Alarm Systems, and must be verified to CAN/ULC-S537-13 Standard for Verification of Fire Alarm Systems. Appropriately amended testing forms can be found in our library. UPDATE: Alberta has adopted NBC 2010 and NFC 2010 as their Alberta Building Code 2014 and Alberta Fire Code 2014 (respectively). The Verification Standard referenced in the ABC is CAN/ULC-S537-13. The Inspection Standard referenced in the AFC is CAN/ULC-S536-13. You can download versions of BOTH Standards from our FORMS page. |

|

||||||||||||||||||||||||||||||||||||||||||

|

What procedure should I follow if the FAS I’m testing doesn’t comply with the installation standard? That depends on what standard you’re testing to. If it’s CAN/ULC-S536 (Annual Test) you should make note of any deficient items as you would normally (keep in mind that CAN/ULC-S536-13 actually DEFINES what a Deficiency is). Remember, you are testing the devices that are connected to the system, and you are doing so to a different standard from that of the technician that performed the Verification Inspection. Should you “tag off” on the system? By all means do so, but make sure you check (or punch) the part of the tag that states “see log and report”. If you feel the deficiency is substantial enough (the batteries are incorrectly sized for instance), then you should also ensure you check (or punch) the column that states “additional work required”. The example given of the incorrectly sized batteries definitely warrants a RED TAG. You should also provide a copy of your report to the local electrical inspection authority or the Fire Department's Fire Prevention Office. |

|

||||||||||||||||||||||||||||||||||||||||||

|

Should a Verification or an Annual Inspection be carried out on a system that you know to be non-compliant (or that you know will "fail" even before you start)? Where should you "draw the line" (call it a day) and re-schedule? Someone once said "there are no dumb questions, just obvious answers". There are several things that should preclude a reasonable person (or in this case a trained professional) from even starting a Verification or an Annual Test. Obviously if there isn't any power to the panel (or it was displaying a "ground fault") you wouldn't (shouldn't) commence testing until the problem has been rectified. If the panel won't "reset" properly, or is completely unresponsive, testing should be curtailed. You should also not test devices that have been identified as non-compliant such as smoke detectors that aren't cross-listed to the control, or manual stations that do not have (or have never met) ULC Listing requirements. Examples of the latter would include pull stations that only bear a "CSA" mark or that use the round breakable disks which are often replaced with metal washers (Yes, I've actually seen this done!) by building owners because the disks are no longer available or are difficult to source. Performing a Verification on a panel with an active trouble such as an "open" zone or signal circuit is certainly doable, as long as the Verification doesn't extend to the affected circuit. Should you pass such a system? No! In one such example, the "approved individual" showed up on the site ready to commence a Verification on three new Notifier fire alarm systems. The common controls all displayed a "ground fault" trouble, yet a decision to proceed with the inspection was made regardless. He also failed to perform the requisite battery tests, didn't identify missing dead-front panels on the power supplies and a number of other errors that actually compromised the LIFE SAFETY of the building's occupants. To add insult to injury, the Strata was billed for a Verification and the company performing the annual servicing succeeded in burying the report for four (4) years before they lost the contract. It was when a new service agency was appointed to perform the annual testing that all of these deficiencies were finally addressed. |

|

||||||||||||||||||||||||||||||||||||||||||

|

What do you do when you discover a non-compliant system that was installed only recently and verified by the manufacturer (or an individual that was approved by the local authority)? You must notify the local electrical authority and the Fire Department's Fire Prevention Office. Here are examples of some of the installation deviations we've come across recently (keep in mind that in each instance a Verification was conducted by an individual "approved" by the local authority):

|

|

||||||||||||||||||||||||||||||||||||||||||

|

What procedure should I follow if the FAS I’m testing was “passed” last year by another technician, but has deficiencies that weren’t noted? Many jurisdictions have established guidelines and procedures to follow in this instance (if you’re testing in a municipality that subscribes to ASTTBC, you can review their Practice Guidelines). The situation can get complicated if you’re working for the same company as the technician who tagged off on the same deficient system you're testing in the previous year. What you should do in this instance is contact your service manager. Under no circumstances should you tag off on a deficient system without ensuring you either check the “see log and report” or “additional work required” columns (as the situation merits). |

|

||||||||||||||||||||||||||||||||||||||||||

|

What procedure should I follow if I discover that the smoke detectors supplied by my company in previous years are not ULC cross-listed to the control panel? See the previous answer. In this instance, you MUST RED TAG the system (alternatively you can replace the affected units with ones that are compatible). You can check if the smoke detectors on the system you're testing are compatible here. |

|

||||||||||||||||||||||||||||||||||||||||||

|

What's the difference between a supervisory alarm and a trouble signal? A "trouble" indication on a fire alarm system represents a problem that may adversely affect the operation of the system (as a whole). In most cases, this must be addressed by trained service personnel. Examples of a "trouble" signal are: AC power failure, battery trouble, ground fault, indicating circuit "open", signal circuit "short" or "open". A "supervisory" signal is an "off normal" indication of a monitored device. In most cases this type of signal doesn't require the response of trained service personnel. Restoring the monitored device to "normal" and resetting the fire alarm system usually clears this type of indication. Examples would be: sprinkler "low air", sprinkler "low water", generator "trouble", fire pump "trouble", movement of a sprinkler valve handle, heat trace power failure (or common trouble), etc. It is important to remember that a supervisory signal often triggers a relay in the fire alarm's common control that is separate from the "trouble" contact. You must ensure that any offsite monitoring connections take this into account. |

|

||||||||||||||||||||||||||||||||||||||||||

|

CAN/ULC-S536-04 (Standard for Inspection and Testing of Fire Alarm Systems) 2004 Edition introduces some significant changes to the way conventional and addressable fire alarm panels are tested. Are you required to adopt these changes? How will they impact testing times and ultimately, the building owner's costs? The changes to the testing standard are significant in one major respect. They will increase the time required to perform the annual test and inspection on all supervised and addressable fire alarm systems and ultimately impact the cost to the building owner for the service. If you are either a CFAA certified or ASTTBC registered technician you must incorporate the changes in the Standard in your testing procedures. If either you or your employer is reluctant to do so you are not conforming to the Standard and may well invalidate the test. This will definitely INCREASE the associated costs to the building owner as additional time must be added to perform the physical testing as well as properly complete the documentation required. It goes without saying that a REDUCTION in cost would be problematic for most legitimate service providers to justify. If the proper testing is being done (and documented), and the costs don’t increase, that would be termed a “business decision” that will definitely have an adverse effect on the provider’s bottom line. Ultimately it’s up to the business’s owners. It’s been my experience that building owners that are looking for cost reductions and targeting the life safety service company to provide them, aren’t really worth pursuing. They’ll want a cheap inspection and will quibble over every comment you make on the report. It goes without saying that if there are deficiencies identified it will be an almost futile exercise to mention them. TIP: Our forms reflect the most current version of the Standard. CONVENTIONAL SUPERVISED FIRE ALARM SYSTEMS: Section 5.7.11 is entitled Conventional Circuit End-of-Line Device and requires you to test each input circuit and output circuit end-of-line devices for open circuit (supervision), short circuit (alarm or supervisory), and ground fault conditions. You must, furthermore record the results of each test in the inspection report. What this means is that you will have to FIND every end-of-line device (it's usually mounted on a single gang plate which is appropriately labeled), and drop it to perform your tests. This will add approximately ten (10) minutes for every zone on the system. On older systems, you may have to hunt for them as they may have been mounted behind the last device in the circuit and not on an identifiable plate. You must list each device in the test record along with its location. The number of end-of-line devices should match the number of active zones on a conventional fire alarm system. TIP for PMA Sales Staff - You can easily calculate the additional time required to complete the annual inspection by counting the number of conventional zones displayed on the common control panel and multiplying by 0.2 (Example - Your panel has 30 initiating and signaling circuits. The time to test the end-of-line devices would be 30 X 0.2 = 6.0 Hours). Note: You should allow for some additional time if the locations of the end-of-line devices are not readily apparent or you can't determine how many signaling circuits there are on the system. Tech Tips: Since you have to drop each end-of-line device to perform the required testing above, I would also suggest that you record the VOLTAGE at each device at the same time. This will enable you to identify potential problems on the zone (if the voltage changes dramatically from one year to the next). It will also assist you in determining if circuit powered devices (like smoke detectors) are receiving their rated voltage and that the voltage drop from the panel is within the manufacturer's specifications. Exercise caution in removing painted end-of-line plates as you could damage the surrounding drywall. Use a sharp knife or screw-driver to score the paint around the device before you remove it. Keep in mind that it is permissible to mount an end-of-line resistor inside a single device (this most often occurs on a sprinkler flow or valve tamper switch). ADDRESSABLE AND LARGE NETWORKED FIRE ALARM SYSTEMS: There are some additional tests required specific to these types of systems. These include: “5.6.2 - Where fault isolation modules are installed in data communication links serving field devices, wiring shall be shorted on the isolated side, annunciation of the fault confirmed, and then a field device on the source side shall be operated and activation confirmed at the control unit or transponder. 5.6.3 - Where fault isolation in data communication links is provided between control units or transponders and between transponders, introduce a short circuit fault and confirm annunciation of the fault and operation outside the shorted section between each pair of: This means that the testing technician must be able to locate and identify the applicable fault isolation modules. Most have an LED placed prominently on the face of the cover plate, but some (like the GE Security SIGA-IM) have no discernible indicators (when mounted on 4X4 boxes with covers). It's been fairly common (in installations I've seen) that the modules are located inside one of the main control cabinets (or in a cabinet mounted adjacent to it). Where are other isolator modules located? Look for them either mounted in a 4X4 box next to the common control or as the first device on a specific floor. TIP for PMA Sales Staff - You should deal with fault isolators the same way you would with the end-of-line device tests unless you can confirm that they're all located in a central location (or cabinet). In the latter instance you can use a 0.1 multiplier to determine the additional time required. In order to comply with Section 5.7.11, you must first identify all conventionally terminated monitor modules. These are predominately located in the building's sprinkler room and used to supervise alarm valves, flow switches, and tamper switches on sprinkler riser valves, fire pump valves, back-flow preventers, and the like. You should also check stairwells for valves and flow switches. Monitor modules are normally mounted on 1110 or 4X4 steel boxes. Some (but not all) will be identified with the zone and circuit numbers on the plastic (or metal) covers. TIP for PMA Sales Staff - Chances are that a review of the previous inspection report will identify the specific conventional type devices that were tested. While it's not always "a given" that each valve or supervisory device is individually zoned, for the purposes of a "rough calculation" you would be safe in assuming so. Use the same formula given in the Conventional Panel TIP. TECHNICAL NOTES: What should you do if the end-of-line resistors don't report a ground fault condition? You will record the results of your testing on the individual device test record. If you observe that the back-box isn't properly grounded, you could expect that the test for ground-fault won't yield the required result. On some older systems, only two conductor wire was often run to each device. Does this deserve a RED TAG? No, however, if the system was installed after 1992 (when grounding of back boxes was first required in the CAN/ULC-S524 Installation Standard), then this should be recorded as a deficiency. What if the end-of-line resistor isn't mounted on a proper plate (in some instances it could even be located in the last device on the circuit)? You must record your findings on the individual device test record and (in instances where there are two or more devices on the circuit), you should also make recommendations that the resistor be relocated to a proper mounting plate next to the last device on the circuit. |

|

||||||||||||||||||||||||||||||||||||||||||

|

The monthly test of my fire alarm system requires me to check the stand-by battery (terminals and general condition). To do this, I have to remove the panel's dead-front. This has a rather large warning sign that states I should disconnect all sources of power before attempting to remove it for service. How can I safely do this? Contact your fire equipment service provider and request that they provide you with the necessary detailed information that will enable you to perform this function. If you're still uncomfortable with the thought of removing the dead front, or have other concerns relating to the required monthly testing regimen, it may be possible to have them perform the service for you. Many fire safety companies provide this on a reduced fee basis (if it's done as part of an annual agreement). WARNING! On many older panels (and even some incorrectly installed newer ones) there is a distinct probability that high voltage AC (110) is terminated to some of the common control relays. Removing the dead front on these panels may expose you to an unacceptable level of risk and as such might be the case this should only be performed by trained technicians. You should make a notation in the monthly log to this effect if you are uncomfortable with performing this task. |

|

||||||||||||||||||||||||||||||||||||||||||

|

Is it permissible to use a UL® listed fire alarm device on a Canadian system even if they're both made by the same manufacturer? In Canada, you can only use ULC® listed devices on a ULC® listed fire alarm panel. Conversely, you can't use a ULC® listed device on a UL® listed fire alarm panel in the United States. The "cUL®" mark is the only one that is recognized as having "no barrier" for use in either country. Using a non-listed device on a listed fire alarm panel is strictly forbidden and would invalidate the ULC® (or UL®) listing. CAN/ULC-S524-06 (Installation of Fire Alarm Systems) states in Section 3.1.3:

"Devices and equipment used in a fire alarm system , and the interconnection to the fire signal receiving centre, shall comply with the following Standards: Tech TIP: If your employer is sourcing fire alarm product from an agency outside of your country's testing jurisdiction for use on a listed fire alarm panel, you cannot install it, and you cannot validate such an installation by accepting (or passing) it. |

|

||||||||||||||||||||||||||||||||||||||||||

|

What's the acceptable voltage drop between the fire alarm control panel and the end-of-line resistor? CAN/ULC-S524 Section 3.4.4 states: “The voltage drop and power dissipation on any circuit shall not prevent the proper operation of that circuit and shall be in accordance with the manufacturer's installation instructions.” This can vary significantly between manufacturer, panel models, and modules. That's why it's really important for you to be able to reference the installation manual for the panel you're testing. You'll also be able to determine if the correct gauge of wire has been used for the estimated length of the run. |

|

||||||||||||||||||||||||||||||||||||||||||

|

How often must a fire alarm system be tested in Canada (the original question asked about British Columbia but the answer applies to any Territory or Province in Canada)? The Inspection Standard for Fire Alarm Systems (CAN/ULC-S536-04) identifies three periodic tests which every fire alarm system IN CANADA must undergo. Most Provincial/Territorial Fire Codes will no doubt reference these tests as well. THE DAILY TEST involves a visual inspection of the fire alarm system's "common trouble" and "power on" indicators. If you're a building owner or manager you should also be performing your daily inspection as outlined in the building's Fire Safety Plan. THE MONTHLY TEST requires that a manual pull station be activated (on a "rotational basis") and that all the audible alarm signals in the building sound. The appropriate zone indicator lamp must also illuminate at both the common control and any remote annunciators. In addition, the standby batteries must be inspected. This may require the removal of the panel dead front to access (which we have addressed in a previous FAQ). If the building is equipped with fire phones and an emergency paging system, one circuit from each system must also be tested on a "rotational basis". It's recommended that all of these tests be performed concurrently to the monthly emergency generator and building fire pump tests in accordance with the requirements of the building's Fire Safety Plan. In most cases the building owner or manager can perform and document these tests. NOTE: Building owners and managers are also required to fill out another testing form called the Building Monthly Test Form (in accordance with the published Fire Safety Plan). A sample of this document can be viewed HERE. THE ANNUAL TEST involves a detailed test of every device in the fire alarm system and requires the services of a qualified technician to carry out. |

|

||||||||||||||||||||||||||||||||||||||||||

|

On an annual fire alarm test to Canadian Standard CAN/ULC-S536-04(-13), is it permissible to skip devices that are either hard to reach or inaccessible for other reasons (i.e. a tenant in a multi-residential occupancy refuses access or isn't home)? Definitely not. There is no provision in the standard that allows a technician this sort of leeway with the exception of extremely high devices (which might require specialized equipment to access), and dangerous industrial processes like those found in chemical or production plants, reactors, factories, and the like (you must document the testing dates for these devices and they must be accessed every two years). Elevator shaft devices don't count as access can be easily arranged with a qualified elevator technician for the day of the annual test. Inaccessibility to a residential suite may involve an additional expense to the tenant that refused access or to the building owner if proper notices weren't given. |

|

||||||||||||||||||||||||||||||||||||||||||

|

When testing a (commercial) fire alarm system, is it permissible to bypass (or disconnect) the NAC circuits to keep down the noise? Most definitely and by all means do so! The Testing Standard actually requires that you test at least one device in every zone with the output circuits (includes notification appliances) connected. The rest of the devices on the zone can be tested with the outputs and signals bypassed. On larger buildings (including shopping malls), it may be prudent to ring the bells (perform your audibility and functional testing) at a specific time (usually early in the morning, late in the day, or even outside of normal business hours) so as to limit the nuisance factor for patrons and tenants alike. It is important that appropriate Alternative Measures (as identified in the Appendix to the Testing Standard) are employed in order to notify tenants, patrons, and the public in the event of an actual emergency! You don’t want to get caught up in a mistake like this! Additional information in the latest version of the Canadian Testing Standard can be found in this FAQ. |

|

||||||||||||||||||||||||||||||||||||||||||

|

I know that smoke and heat detectors cannot be painted (for obvious reasons), but the building I'm inspecting has bells, insuite buzzers, and end-of-line resistor plates painted to match the surrounding wall surfaces. One bell is even covered with the same wallpaper as the wall. Should I pass these devices or should they be replaced? Good question! Any fire alarm device which has the notation "Do Not Paint" clearly marked on its surface (and readily visible) must be replaced if it has, in fact, been painted or otherwise altered from the condition it was in when it was newly installed. I would be prepared to make one single exception when it comes to end-of-line resistor plates. Most are plastic these days and the “resistor” symbol is moulded into the cover. Metallic plates, however, would have to have a label affixed to them identifying what they are. If that’s painted over, it could present a problem. With respect to the painting of fire bells (or covering them with wallpaper), you are in fact altering their sound characteristics and could even affect the units audibility level (not to mention you'd paint over the UL/ULC label which would invalidate this device's listing). This cost must be covered by the individual that authorized the painting. If it's in an apartment suite, then the tenant/owner bears the responsibility for its replacement (if it can be determined that they actually instigated it). If a painting contractor is involved, then they should definitely have known better (and should bear the responsibility in this case)! |

|

||||||||||||||||||||||||||||||||||||||||||

|

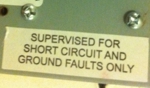

How do you test fire alarm isolator modules? Excellent question! The testing methods vary slightly depending upon the type of isolator (as well as who manufactured it). It’s a good idea to have the installation instructions handy for the model of isolator you’re testing. This will usually include a recommended test procedure that might differ slightly from what you read here. There is additional information regarding installation methods for the various isolator types located in this Special Report! NOTE: The manufacturer’s sugggested test methods should be used in EVERY case. First of all, you have to recognize that there are now THREE types of isolator modules available for use in a fire alarm system. Let’s look at each one and examine the suggested testing methods: SLC (Signalling Line Circuit) or DCL (Data Communication Line) Isolators: These units ensure survival of the two wire communications loop which serves addressable (sometimes referred to as “analogue”) fire alarm field devices (smoke detectors, pull stations, heat detectors, etc.). Many of the more popular isolators out there are what’s termed “dumb” devices (in other words, they don’t have much in the way of internal “smarts”). They’re essentially a relay module that’s designed to isolate a short on the data circuit within a certain area or that may affect a number of devices assigned to the isolator. Regardless of what method they employ to identify a fault on the data loop, their main function is to isolate that fault to a few devices while ensuring the overall integrity of the system isn’t compromised. Testing method - There are two termination points on every isolator. One is an “in” from the common data loop and the other is an “out” to the field devices it serves. Short the “out” side to ensure the unit functions correctly (yes, this means that you will have to remove the cover on each unit!). Depending on the number of devices on the “out” side, you should see a string of error messages on the common control that are most commonly identified by the phrases “missing device” or “device error”, or “data loop short”. Maintain the short until you have scrolled through and noted each device that fails to report. Part of your “test” ensures that the total number of devices for each isolator does not exceed the manufacturer’s maximum limit. If more than one floor area’s devices fail to report while the short is in place you will have to note this as a deficiency on your report! If the isolator you’re testing happens to be bi-directional proceed to short the “in” side. Maintain the short until your helper has scrolled through and noted each device that fails to report. Field devices which employ isolator bases must also be tested. If the system you’re testing employs these units (it’s usually the first smoke detector on the loop), you’ll have to find an addressable device (a manual station is usually the easiest to access) downstream of the isolator. Drop it and short the loop terminals from here. Maintain the short and have your helper scroll through and note each device that fails to report. Power Supply Isolators: These units ensure that the common power supply buss is not compromised by a short on one (or a series) of the field devices it serves. These are fairly uncommon on systems installed to date, but where they are used, an appropriate test must be conducted to ensure their operation. Testing method - While shorting a power supply is not normally recommended, opening the circuit on the “out” side of the isolator will identify the devices it protects. You must ensure the maximum current for the unit is not exceeded (or the recommended maximum number of devices). Use your meter (set to “amps”) to determine what each isolator is handling. In EVERY case, follow the manufacturer’s suggested test methods and note the results in your report. Notification (Bell/Buzzer Circuit) Isolators: In British Columbia (and most jurisdictions across Canada), the NBC mandates that insuite sounder devices must be installed on a separate signalling circuit from the common area notification appliances. For more detailed information, please read our FAQ which details the Code requirements. There are two tests which must be performed at each isolator. Normally these units are installed in the common area corridor outside of the suites they serve. They’re always located behind a suitable cover which identifies them as a fire signalling component or fire alarm device. There are two “flavours” available: “supervised” and “unsupervised”, The unsupervised isolator is NOT allowed by Code or the installation standard (CAN/ULC-S524). If you come across one (they will have a label affixed to them identifying them as such), you must fail the unit. No further testing is required. This is a label on an Caution! Use of ANY unsupervised Testing method - There are two phases to the required testing. One is performed while the system is in normal supervisory mode, the other is performed while the system’s sounders are active. For these tests, it is recommended they be performed inside the suite the unit serves. You will notice that there are two “outputs” on each isolator (it serves two separate suites or units). All in-suite devices controlled by an isolator are wired in a Class “A” loop. Step 1 - Remove and drop any one of the in-suite buzzers. If all of the above tests are completed satisfactorily, you can move on to the next suite on the floor (after reinstalling the buzzer that is!). NOTE: If, in step 5, none of the buzzers in the suites sound, then the notification appliance circuit is programmed incorrectly! You must note this on your report. Some systems utilize a jumper setting to activate the signals if isolators are on the circuit. Other systems require access to the physical panel programming to enable this feature. |

|

||||||||||||||||||||||||||||||||||||||||||

|

Is a sound level pressure test required on an annual basis by CAN/ULC-S536? Not at this time. You are however advised to ensure the audibility level is acceptable. This is strictly a judgement call. The relevant section of the “-04” version of the Testing Standard is 5.7.9 which states in sentence 5.7.9.1 C: “The audibility of the alert signal and/or alarm signal and of voice messages shall function as intended throughout the area served by the device;” It’s been my experience that a lot of things can change in a building that could adversely affect the primary function of any fire alarm system (to alert the occupants to danger). It behoves the seasoned professional to recognize when that ability is impaired to the point where the installation of additional signaling appliances may become necessary. Please ensure appropriate comments are noted on your report! |

|

||||||||||||||||||||||||||||||||||||||||||

|

How much notice is required when performing a fire alarm inspection in a residential suite? In British Columbia (where I work), notification of tenants that are renting a suite falls under the Residential Tenancy Act (RTA). This requires twenty-four hours written notice before you can even enter the suite (unless there’s a dire emergency like a flood or fire). For those tenants that actually OWN a suite, they are subject to the Bylaws of the Building’s Strata. Regardless, the inspection of in-suite fire/life safety devices is mandated by the Provincial Fire Code. Your jurisdiction may have additional provisions/rules which may apply in either case. It’s best to check with them before you post the notices. |

|

||||||||||||||||||||||||||||||||||||||||||

|

What does “annual in-suite fire alarm inspection” mean? What do you suggest I do to prepare? Can I refuse to have this done? Every year (in Canada), Provincial and Territorial Fire Codes mandate that a building’s fire alarm system be tested to something called CAN/ULC-S536 (Canadian Standard for Annual Fire Alarm Testing). This means that EVERY device that forms part of your building’s fire alarm system must be tested to ensure it will function adequately in an emergency. If you rent an apartment, your Landlord will provide you with appropriate notification that entry to your unit is required to test the Smoke Alarms, fire alarm audible signal devices (usually a wall-mounted buzzer), and any system fire detectors. If you happen to own an apartment (or condominium) in a building with a fire alarm system, the devices I mentioned previously must still be tested. You cannot refuse access to your unit for this test as it is MANDATED by the Fire Code. To do so will result in a rather unpleasant visit from your local fire department who will ORDER you to comply with the requirements of the Code. As I mentioned, many apartment tenants and owners are provided with written notification that access will be required. In order to expedite the testing, it might be prudent for you to leave your unit’s key with a neighbour or friend who will attend the premises and allow the testing agency access to complete the service if you anticipate you might not be home. If you have pets or young children that might be disturbed, or become anxious, by prolonged exposure to the noise that’s part of a system wide test, it is suggested that you remove them from the building entirely for the duration of the testing. NOTE: If your building employs visual alarm signals (fire strobes), and you, or a loved one, have a nervous disorder (such as epilepsy), please ensure you take the appropriate precautions. It is extremely important, in this instance, that the buildings’ fire safety plan contains this information in the “Tenants Requiring Assistance” notice so that first responders are aware. |

|

||||||||||||||||||||||||||||||||||||||||||

|

How many turns of a sprinkler isolation valve are required before a supervisory condition has to be annunciated at the fire alarm control panel? CAN/ULC-S536-04 states in Section 5.7.8.2.1: “Each shut-off valve position supervisory switch shall be tested to determine that within two turns of the valve handle, or when the stem of the valve has moved 20% from its normal position, it shall result in an audible common trouble signal and a visual indication.” The newest edition of the Standard (-12) the “audible common trouble signal” has been changed to latching supervisory signal. BCBC 2006 Sentence 3.2.4.9.2 states: “An automatic sprinkler system shall be electrically supervised to indicate a supervisory signal on the building fire alarm system annunciator for each of the following: (a) movement of a valve handle that controls the supply of water to sprinklers; ...” NOTE: Many older type fire alarm panels may not be capable of providing a latching supervisory signal, but will, instead, indicate a common trouble. In this instance, you should note they type of signal that is indicated on the report form. If the zone is shared between the isolation valve and the alarm switch, you must ensure that the alarm overrides the trouble condition. To do this, close the valve enough to annunciate the trouble and then perform your alarm test. |

|

||||||||||||||||||||||||||||||||||||||||||

|

Do you have to maintain a fire watch while you’re performing an annual test on a fire alarm system? What alternative measures should you employ while an annual fire alarm test is being performed? Appendix B (Informative) of CAN/ULC-S536-04 is entitled “Alternate Measures for Occupant Fire Safety” and reads: “B1 In the event of any shutdown of fire protection equipment or parts thereof, the Fire Department and building occupants/owner should be notified. Instructions should be posted as to alternate provisions or actions to be taken in case of an emergency. These provisions and actions should be acceptable to the Chief Fire Official and be in accordance with the accepted Fire Safety Plan. B2 An attempt to minimize the impact of inoperative equipment should be made (i.e. where portions of a sprinkler, fire alarm system and standpipe system are taken out of service, the remaining portions will be maintained). Assistance and direction for specific situations should be sought from the Fire Department and be in accordance with the accepted Fire Safety Plan. B3 Procedures to be followed in the event of shutdown of any part of a fire protection systems are as follows: A Notify the Fire Department and the monitoring station. Give your name, address and a description of the work and when you expect it to be completed. The fire Department should be notified in writing of shutdowns longer than 24 h; B Post notices on all floors by elevators and at entrances, stating the work and when it is expected to be completed; C Have staff or other reliable person(s) patrol the affected area(s) at least once every hour; and D Notify the Fire Department, the monitoring station, and building occupants/owner when work has been completed and systems are operational.” |

|

||||||||||||||||||||||||||||||||||||||||||

|

Are you required to list each device during a fire alarm system annual inspection? Yes, you are. You must list (and test) every device connected to the fire alarm system. This includes end-of-line devices. You must also note the type, manufacturer, and model number of each device and, more importantly, confirm that (where the device draws power from the fire alarm) it is fully compatible (ULC cross listed) to the system. Exceptions must be listed in the report as deficiencies. See also the procedure for RED tagging a system located in our General FAQ page. How do you test a sprinkler flow switch (or alarm pressure switch)? The Reference Clause in CAN/ULC-S536-13 is 6.7.8.1.1: “Each waterflow detecting device shall be inspected and tested to confirm operability, including the following functions, as applicable: A Waterflow detecting devices (paddle and pressure type) including associated input circuits, shall be tested by an appropriate waterflow means; and B Time delay setting shall be recorded in the individual device record (Refer to Appendix C3.2, Individual Device Record.)” Here’s the step-by-step procedure you should follow: 1. Remove the switch’s cover. This should activate the cover tamper and cause a “trouble” indication on the appropriate zone of the common control. Make sure you note on your test report if NO TROUBLE annunciates on removal of the cover and you see that the supplied tamper switch isn’t wired into the circuit. Notes: When testing an alarm pressure switch, the alarm should occur immediately following activation of the switch (there is normally no delay). A delay of at least fifteen (15) to twenty (20) seconds on a paddle type flow switch is desirable to prevent false alarms that may result from a “water hammer”. Where MULTIPLE flow switches are wired to the same zone, you should remove ALL of the covers once you’ve completed the individual tests above and repeat the alarm test procedure with each switch. What’s the purpose of removing the device’s cover? It’s two-fold. First, you’re ensuring that removal of the cover results in a specific “trouble” on the fire alarm system. Second, you’re ensuring that, with the cover removed, the alarm over-rides the trouble indication. If it doesn’t, the switch is wired incorrectly! NOTE: Some newer model sprinkler devices employ tamper-proof screws for the cover. In this case, a tamper switch may not be employed. Make sure you make note of the model number and ensure this is the case! |

|

||||||||||||||||||||||||||||||||||||||||||

|

Is an inspection of the fire alarm control panel required by the Standard? Most definitely! If you look at the test report, there is an entire section that requires you to visually inspect the fire alarm control panel’s modules, terminations, and general condition. This will require you to remove the panel’s dead-front. Review an example of a test report here! |

|

||||||||||||||||||||||||||||||||||||||||||

|

How often do the fire alarm bells in a (175 suite) condominium have to be tested in British Columbia? The periodic tests required of any fire alarm system in Canada is described in this FAQ. |

|

||||||||||||||||||||||||||||||||||||||||||

|

In which edition of CAN/ULC-S536 did it become mandatory to test end-of-line resistors? It was first introduced and made a requirement in CAN/ULC-S536-04. It continues to be a requirement in the latest version of the Standard as well. You must test all input circuit and output circuit end-of-line devices on an annual basis. The reference Clauses in CAN/ULC-S536-04 appear in Section 5.7.11 entitled “Conventional Circuit End-of-Line Device”: “5.7.11.1 Each input circuit end-of-line device shall be tested for open circuit fault, short circuit fault and ground fault conditions. The results shall be recorded in the Inspection Report. 5.7.11.2 Each output circuit end-of-line device shall be tested for open circuit fault, short circuit fault and ground fault conditions. The results shall be recorded in the Inspection Report.” The reference Clauses in CAN/ULC-S536-13 have been substantially amended, and appear in Section 6.7.11 entitled “Circuit End-of-Line Device”: “6.7.11.1 Each input circuit end-of-line device shall be tested for open circuit fault, short circuit fault and ground fault conditions. The results shall be recorded in the Individual Inspection Report. Refer to Appendix C3.2. Exception: Where an end-of-line device serving a single conventional device is connected directly to a conventional circuit or a supporting field device, it does not require testing when serving a single field devices that is located within or adjacent to that field device. 6.7.11.2 Each output circuit end-of-line device shall be tested for open circuit fault, short circuit fault and ground fault conditions. The results shall be recorded in the Individual Inspection Report. Refer to Appendix C3.2.” |

|

||||||||||||||||||||||||||||||||||||||||||

|

What percentage of fire alarm devices in a building are inspected annually? One hundred percent (100%). In other words: ALL OF THE DEVICES! There’s more information at this FAQ. |

|

||||||||||||||||||||||||||||||||||||||||||

|

What’s the cost for a typical annual fire alarm inspection? The cost varies with the size and complexity of the fire alarm/life safety systems employed in your project. You can get a fair idea of what the cost should be by using our Inspection Time Calculator. In most instances we can pretty well guarantee that you’ll get some change back from your million dollar bill. |

|

||||||||||||||||||||||||||||||||||||||||||

|

Can a buildings’ maintenance personnel conduct fire alarm testing in accordance with the Standards? The daily and monthly inspection and testing of the fire alarm system is normally conducted by personnel appointed as the Fire Safety Director or Deputy Fire Safety Director (or their designates) in your building’s Fire Safety Plan. These tests are outlined in this FAQ. As for the ANNUAL testing, this would depend on how your local jurisdictional authority is going to interpret Appendix “A” of CAN/ULC-S536-04, which reads: “Any person who performs the annual test and inspeciton of a fire alarm system should be knowledgeable about this Standard and have received suitable formal training or sufficient experience acceptable to the authority having jurisdiction.” It’s been my experience that many building owners don’t want to take on the liability exposure associated with ensuring the system is in full compliance with the Standard (let alone the other life safety equipment that’s also required to be maintained by the applicable Provincial Fire Code). |

|

||||||||||||||||||||||||||||||||||||||||||

|

What does a smoke detector sensitivity report look like? The report the Testing Standard requires a technician to submit looks very similar to the fire alarm test documentation we include as part of the Building Annual Test Report FORM we provide. If you turn to the Individual Device Test Record C3.2, you should expect to see an entry beside each line that describes the operational test of a smoke detector (the “Remarks” column). |

|

||||||||||||||||||||||||||||||||||||||||||

|

Can a fire alarm technician test a fire sprinkler system? The individual performing the annual inspection and test of a fire alarm system in Canada must follow the provisions of the applicable Standard (in this case either CAN/ULC-S536-04 or CAN/ULC-S536-13 depending on which version of the National Fire Code of Canada your province or territory has adopted). He/she is required to test sprinkler flow and supervisory switches for operation and correct annunciation at the fire alarm control panel. In British Columbia and some other Canadian jurisdictions, fire alarm technicians may also be conversant with (and trained to perform) the requirements of the sprinkler testing Standard (NFPA 25-2014 is actually the specified Standard in NFC 2015 which has been adopted by many Provinces). In the latter instance, the technician could possess some form of documentary evidence such as a training certificate, stamp or another suitable means of identifying himself as being acceptable to the authority having jurisdiction. Keep in mind that it is the authority having jurisdiction that is the final arbiter of any technicians’ competence to perform the required testing mandated by your Province’s Fire Code. |

|

||||||||||||||||||||||||||||||||||||||||||

|

There’s a new column in the Appendix “C” testing form for CAN/ULC-S536-13? What does it mean, and how do you use it properly? The new column is in Section C3.2 - The Individual Device Test Record. It’s labelled “Output Circuit Operation Confirmed”. The Standard allows you to test a fire alarm system with the output circuits disabled (this is primarily to prevent such annoyances as elevator homing, fan & damper activation, and audible and visual signals from interfering with the normal operations of a project that’s undergoing repeated alarm activations during an annual inspection). The Standard does stipulate however, that at least one initiating device IN EVERY ZONE must be tested for correct output circuit operation. The referenced column was added because it was felt a “check-mark” was the simplest way to document the proper test. Section 6.2.1 is entitled “General” under “6.2 CONTROL UNITS AND TRANSPONDERS” in CAN/ULC-S536-13: Clause 6.2.1.1 reads: “One conventional field device in each input circuit shall be operated to confirm appropriate output circuit operation. Other conventional field devices within the circuit may be tested with the output circuits inhibited.” Clause 6.2.1.2 reads: “One conventional field device in each input circuit monitored by a supporting field device shall be operated to activate applicable alarm signal devices. Other conventional field devices within the circuit may be tested with the output circuits inhibited.” Clause 6.2.1.3 reads: “One active field device in each zone shall be operated to confirm appropriate output circuit operation. Other active field devices within the zone may be tested with the output circuits inhibited.” You’ll likely notice that the newest version of our Building Inspection Test Forms are based on the new Inspection Standard and include the additional column. |

|

||||||||||||||||||||||||||||||||||||||||||

|

How often do fire alarm devices in elevator shafts require testing (in Canada)? Annually (every year). No exceptions exist in the annual testing Standard, but for devices that are hard to reach or involve access to dangerous processes. These require testing every TWO (2) years and you must affix a label to the device indicating the date it was inspected. |

|

||||||||||||||||||||||||||||||||||||||||||

|

Is it against Code to test heat detectors with a torch in British Columbia? Most definitely YES! (And this answer applies to EVERY PROVINCE AND TERRITORY IN CANADA!) CAN/ULC-S536-13 Sentence 6.7.3.1 (underlined for emphasis): “Each heat detector shall be tested to confirm operability. (Refer to Appendix G, Testing of Heat Detectors.) NOTE: An open flame shall not be used for testing the operation of heat detectors.” Sentence 6.7.3.2: “Each restorable heat detector shall be tested by using a heat source reproducible in its intensity, as recommended by the manufacturer of the device, to initiate an alarm.” |

|

||||||||||||||||||||||||||||||||||||||||||

|

I work for the public sector performing annual testing and Inspections of fire alarm systems. After advising staff, the monitoring station, and the fire department, the fire alarm signals and ancillary devices are disabled so that disruption to the building’s occupants during testing is kept at a minimum. One person constantly monitors the fire alarm panel while another person commences testing the field devices. I have asked the local Fire Marshall if a Fire Watch is needed in this scenario, and his response was to advise the supervisory staff to follow the published fire safety plan. Again, I specifically asked if a Fire Watch is needed, and again, his answer was the same. I have asked fellow workers and they say you don't need one because someone is sitting at the fire alarm panel. I have read the OFC (Ontario Fire Code), the ULC standard, and both state that if fire alarm system is disabled for any reason a Fire Watch must be established. It does not say anything about exceptions or extenuating circumstances as would be the case regarding an annual inspection. I have been following your site for quite some time, and I know you've been in the industry for a long time, and I hope you can give me your 2 cents. Do I need to institute a Fire Watch? An interesting question, and one that’s frequently asked! We agree there’s a lot of confusion out there about how to interpret this section of the Standard. If all you’ve shut down are elevator recall functions, audible signals and other ancillary outputs and you have a qualified individual at the common control that can respond to an alarm event in an area of the building that’s not undergoing testing, then you have to exercise something called “common sense”. If you haven’t shut down any detection means, a fire watch shouldn’t have to be maintained because you’re not affecting the system’s ability to detect a fire, only respond to one. It would be fairly simple for the individual at the common control to reactivate notification and output circuits thereby ensuring the building’s occupants are safely evacuated and the fire department notified. So if you ensure your publicly posted testing notices provide an “alternate notification means”, and that the individual at the common control clearly understands the “actions” he’s going to have to follow in response to an alarm event outside of the area being tested, then you will have complied with the suggested procedures outlined in Appendix “B1” of CAN/ULC-S536-04. Now, for the sake of further clarity. If you’ve just finished testing the 8th floor and have moved on to the 7th, and you get an alarm from a smoke detector on the 8th, chances are it’s not an actual fire but is caused by some residual test smoke in the hallway. YOU will still have to investigate before having your guy press “reset”. If the alarm is coming from a floor you haven’t yet tested (or from one where the testing has been completed for more than a few minutes), then don’t take any chances. Have your helper at the common control activate the building fire alarm’s output functions and commence evacuation while you carefully investigate the situation further. When you’re shutting down DETECTION or ALARM initiating circuits (or devices), you should follow the suggested guidelines in Appendix “B3C”: “Have staff or other reliable persons(s) patrol the affected area(s) at least once every hour.” “B2” of CAN/ULC-S536-04 Appendix “B” provides some guidance but it’s very generic and would suggest that further clarification (if needed) should come from the AHJ or the building’s Fire Safety Plan. “An attempt to minimize the impact of inoperative equipment should be made (i.e. where portions of a sprinkler, fire alarm system and standpipe system are taken out of service, the remaining portions will be maintained). Assistance and direction for specific situations should be sought from the Fire Department and be in accordance with the accepted Fire Safety Plan.” |

|

||||||||||||||||||||||||||||||||||||||||||

|

How do you properly test a manual pull station? The proper way to test a pull station is accomplished by operating it in accordance with the instructions printed on its face. CAN/ULC-S536-04 (Standard for Inspection and Testing of Fire Alarm Systems) states in Sentence 5.2.1: “Each manual pull station shall be inspected and tested to confirm operability, as applicable: A Mounted with sufficient clearance to facilitate ease of access and proper operation; and B Tested according to the operating instructions for the station. For two-stage manual pull stations, the first and second stage functions shall also be confirmed.” In CAN/ULC-S536-13 Section 6.7.2 has been slightly modified: “NOTE: Tamper or protecting covers for manual stations shall comply with CAN/ULC-S528, Standard For Manual Stations for Fire Alarm Systems, Including Accessories. 6.7.2.1 Each manual stations shall be tested by actuating the device as intended. 6.7.2.2 Each two stage manual station shall be tested by actuating the device as intended so that the first and second stage functions are confirmed. 6.7.2.3 For manual stations with ancillary contacts, ancillary functions shall also be confirmed and recorded.”

|

|

||||||||||||||||||||||||||||||||||||||||||

|

What version of the annual fire alarm testing Standard should be followed for a Government of Canada building? Government of Canada owned (or controlled) buildings are tested to the latest published National Codes. Annual fire alarm testing must be performed in accordance with CAN/ULC-S536-13, (which is the Standard referenced in NFC 2015). But wait... we’re not done answering this question. Government of Canada buildings also have to be tested by a fire equipment service provider that is ULC Listed under a special Certification Program called Fire Alarm Systems, Inspection and Testing (UWJSC). Under the program, buildings that are required to undergo Certified testing are registered with ULC, and the service provider’s offices become subject to random on-site surveys by a ULC employed local area representative very similar to what happens with the two CAN/ULC-S561 Certification Programs (DAYYC Installation Companies, and DAYIC - Receiving Centres). Companies that elect to participate also have to comply with Bulletin 2014-04, which requires them to perform and document the fire alarm inspection to CAN/ULC-S536-13 from January 1, 2015 onwards. Note: Not all the buildings that are being annually inspected by the Listed service provider have to be formally registered which means the neither the testing methods or documentation (for the non-registered projects) are scrutinized by the reviewer. You’ll often find service providers maintain separate sets of inspection records as a result. The technicians in the employ of a ULC Listed Testing Agency do not need any special Certification over and above what they are required to maintain by the jurisdictional authority. |

|

||||||||||||||||||||||||||||||||||||||||||

|

How do you test conventional fixed temperature heat detectors? Fixed temperature conventional heat detectors cannot be exposed to heat (unless they’re the “restorable” type similar to some of the early Mirtone “button” detectors). The fixed temperature element will permanently fuse at whatever temperature it’s rated at which means the unit will have to be replaced. The testing mandated in CAN/ULC-S536 hasn’t changed over all the years I’ve been in the business. You have to drop this type of detector (which means you have to physically access it), and short the terminals on the back to simulate an alarm condition on the circuit (System Sensor actually suggests you use a shorting wire with a pair of alligator clips on it). Dropping the detector to perform this test also allows you to inspect the unit for damage (including at the terminals). You cannot attach a permanently wired “shorting” device (or wire) to the terminals to make the testing more “convenient”. The Bulletin issued by Kidde for their Chemtronics 500 and 600 Series of detectors is the perfect example of why it is you MUST visually inspect a conventional fixed temperature detector annually! The requirement for testing fixed temperature heat detectors is articulated in Clauses 6.7.1.1 and 6.7.3.3 of CAN/ULC-S536-13, which respectively read as follows: “Each field device shall be inspected to confirm the following, as applicable: A Free of damage; And: “Each non-restorable heat detector shall have the circuits tested by simulating its electrical operation at the wiring connection.” |

|

||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||

The Fire Technicians Network

+1 (888) 340-3473

“We are not a professional union, but together, we are a union of professionals!”

What we’re all about!

We are not affiliated with ASTTBC, CFAA, CANASA, NFPA, NAFED, or NICET (although we encourage you to explore and objectively evaluate the benefits associated with supporting their individual efforts). Membership in the Fire Technicians Network is entirely voluntary. Are you up to the challenge of demonstrating your commitment to public safety and the highest standard of professional practice?

Copyright © 2007 - 2020 The Fire Technicians Network. All Rights Reserved