EDITORIAL

“Sure, some journalists use anonymous sources just because they’re lazy, |

||||||||||||||||||||||||||||||||||||||||

A TECHNICIAN’S SoP AND THE STANDARDS MINEFIELD!Note: The opinions expressed by the Writer are his own, and may not necessarily reflect those of the Fire Technicians Network, its affiliates, sponsors, members and/or Directors. By Frank Kurz “Oh what a tangled web we weave when we first practice to deceive.” “Knowledge is of no value unless you put it into practice.” “We are what we repeatedly do. Excellence therefore, is not an act, but a habit.” “Front toward enemy.” Vancouver, B. C. - In a recent Verification I had been contracted to provide, an event occurred that I’ve experienced only a few times in my career. I was asked to leave. You see, the building manager complained to the contractor that had hired me that what I was doing was going way beyond what he perceived my scope of work should be. I had uncovered a whole host of deficiencies with the system in the complex, but had been specifically hired to Verify only the devices in one of the commercial retail spaces (CRU). Despite the fact that the modification to the fire alarm system included the addition of three speakers and an addressable smoke detector, the manager felt that I wasn’t supposed to test the paging functions, operation of the Data Communications Link serving the space, the connection to the fire signal receiving centre, or the emergency power supplies. My informing him that I was going to fail his fire alarm system just didn’t sit well, and the comments I made about the inadequate testing being performed by the RFPTs employed by his trusted fire protection equipment service provider were simply too much. Tugging on Superman’s cape, is something that the late Jim Croce so eloquently warns against doing in one of his greatest hit songs “You Don’t Mess around with Jim”. It is simply because I cannot abide bad practice, inconsistent testing, and technical ignorance when it comes to servicing and inspecting building life safety systems, that I’ve been pulling the mask off the old Lone Ranger and tugging on Superman’s cape for all these many years. This is also not the first time I’ve been asked to leave a job site. It’s also not going to be my last. And if you know how this Jim Croce song concludes, you’ll understand why I’m not all that worried.

|

|

|||||||||||||||||||||||||||||||||||||||

|

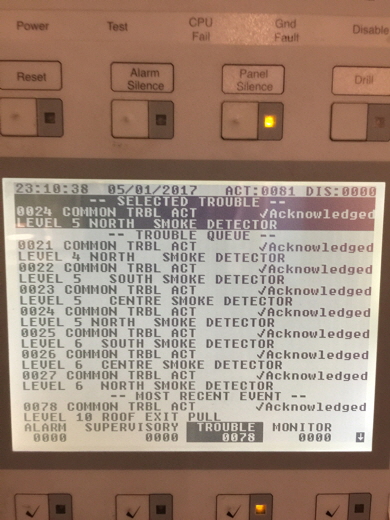

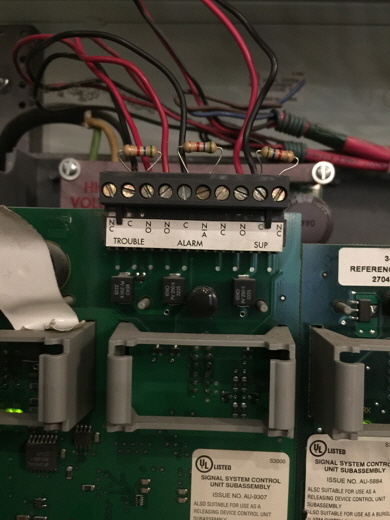

My experience with this particular contractor and building manager perfectly illustrates why our industry is in the state that it’s in. The one page report form (often based on Vancouver’s - now fillable PDF - form) has been utilized by almost every Verification Agency in British Columbia’s Lower Mainland to document a Section 6 modification of a fire alarm system for so long, it’s become the norm (the accepted Standard Report). In fact, it’s the format that’s often all that is expected by many contractors that hire Verifiers. And why not? It’s easy to complete, it covers the basic essentials, it’s simple to digest, and it lets the technician’s employer bill an easy $500 - $1000 (often with a “truck charge”). More importantly, it’s non-confrontational because it doesn’t include any references to the testing or inspection of the system’s control panel, power supply, or other functions that might uncover problems. Everybody’s happy. But what exactly IS a Section 6 MODIFICATION in the actual Standard for Verification of Fire Alarm Systems (CAN/ULC-S537-04)? The very first Clause in this Section states: “Where field devices are added to an existing system, the verification shall ensure that: A Added device(s) are compatible with the control unit or transponder and other devices on the wiring circuit; B Loading of the circuit has not been exceeded; C Emergency power provided is of sufficient capacity for the additional device(s); and D The input circuit to output circuit operation, including ancillary device circuits shall be tested for correct program operation, as per design and specification.” So how does one document these four items on the Appendix “C1” Report form? Neither the sample form provided in the Standard (or the City of Vancouver’s fillable one) references emergency power capacity, correct program operation (which includes ancillary device circuits), or circuit loading. (Vancouver’s form does reference device compatibility with the fire alarm system.) A single page report, even if it includes a list of the new devices with their locations, similar to the C6.2 - Individual Device Test Record, makes positively NO REFERENCE to any of the required testing in this first Clause. Nor can it document any testing referenced in Clause 6.6: “Addition, modification, or deletion of active field device(s) and supporting field device(s), to an existing data communication link shall require verification of the new or altered device(s). In addition, either an operational test of all devices connected to that data communication link shall be performed, or the correct sequence as identified in Cause 6.11 (B) shall be confirmed.” Wow. Note: In the interests of my providing full disclosure in what you’re about to read, I am no longer a member of the CFAA following my decision not to renew at the end of December, 2016. Does anyone reading this believe that ASTTBC or CFAA are in any way knowledgeable about what’s become the industry norm? Of course they are! In point of fact, they are totally complicit in the use of the “single page report” because they turn a blind eye to the practice. They even go so far as to DEFEND IT. When I decided to support the CFAA through a corporate participating membership back in 2012, it was shortly following a British Columbia Chapter Board meeting in which I had been invited to present my views on the subject of Fire Alarm Verification. Within a few days of receiving my Certificate of Membership, I decided to volunteer on the Chapter Board. There was considerable push-back from several of the other Directors (more than one of whom had their companies featured in several Burning Brick Awards we once published). In fact, one of them went so far to suggest that I might be a Nazi sympathizer in a scathing email rebuke for an Editorial I’d written about the City of Vancouver’s dismissal of their City Electrician in which I had quoted the infamous Adolf Hitler. I’ve since used that quote more than once over the years (and NO, I’m not a Nazi). “If you tell a big enough lie and tell it frequently enough, it will be believed.” -- Adolf Hitler What’s become even more obvious, over the last twenty years, is that the system of checks and balances on which both the CFAA and ASTTBC technician certification programmes rely, is broken (kaput in the language that was, coincidentally, native to my parents and Herr Hitler). Service technician members of both these associations are extremely reluctant to actively engage in the complaint process their respective Code of Ethics actually demands when they encounter the shoddy work of others. Why? Because of the possible ramifications to their employers and, by unfortunate extension, to their own employment. The principle behind the concept of a complaints driven policy of self regulation is, in fact, the first thing that’s compromised when a technician member of either of these organizations actually starts WORKING for a living. When you can effectively muzzle professional practitioners responsible for implementing the various Codes and Standards by suggesting it wouldn’t be a good idea to file a complaint, who’s left that has both the knowledge to identify illicit practice, and the ability to follow through with notifying someone in authority? It’s boils down to a handful of individuals (like the more savvy AHJ’s and Building Inspectors). The actual work involved in filing a complaint can also be onerous, time consuming, and the end-result often extremely frustrating (I can testify to this from having initiated several complaints myself). Don’t kid yourself, the decline in the number of complaints ASTTBC has experienced recently, has absolutely NOTHING to do with a sudden reduction in shoddy technician practice or any improvement of the Programme’s oversight. The members of the ULC Working Group currently developing the newest version of the testing and Verification Standards (S536 and S537 repectively), which I happen to Chair, all recognize what HAS to be done to ensure a life safety system is fully functional. We actively strive to improve these Standards to address new technologies and testing methodologies, while at the same time ensuring that as many of the interpretive aspects in the various Clauses are removed or amended to reflect what’s really expected. The newest versions of these Standards, shortly to be released for public review and ballot, have significantly improved Appendices that will take a lot of the guesswork out of what we all have to do as technicians working in the Canadian fire alarm system testing and Verification communities. Annual testing requires ensuring isolators function, smoke detector sensitivity is evaluated and recorded, an open, short, and ground fault is received at the end-of-line, and the emergency power supply is adequate to meet the requirements of the system (the list goes on). Performance of the system must be assured in a comprehensive way, and any work on life safety equipment must be properly documented in accordance with the National Fire Code of Canada (and the relevant Standard). Verification, on the other hand, is a much more comprehensive test/inspection that, in addition to ensuring the fire alarm system is actually INSTALLED in accordance with another Standard (CAN/ULC-S524) and the design, also checks that all field devices are properly terminated, wired and installed in accordance with the manufacturer’s published instructions, and their function (and any required correlations) matches the Sequence of Operation as approved by the authority having jurisdiction. Note: Samples of BOTH testing FORMS have been available on our website from the date we first went on-line. What have CFAA and ASTTBC genuinely done to raise the bar on Practice in the last twenty years? (Note: I’ve picked this number because the ASTTBC Fire Protection Technician Programme hasn’t existed as long as CFAA’s Fire Alarm Technician Certification Programme). Where were they when the controversial issue of outdoor mounted annunciators suddenly appeared a few months back? More importantly, where are they now? The CFAA has only recently decided to include an educational requirement for their technician members annual renewals, but without the pro-active oversight and support the guys with the actual boots on the ground need from a professional association, their practice will continue to be dictated by an employer that kowtows to owners and property managers looking for the lowest price for that tag, along with a report document that’s acceptable to the local AHJ. In CFAA’s case, the Certified Technicians invariably find themselves working for companies that are also participating members of the same organization that certifies their practice (and that exercise significantly more influence through sponsored ads in CFAA’s quarterly-published Journal). The required MANDATORY annual testing that is NOT being performed in many buildings in British Columbia (and across Canada) by technicians with inadequate training or access to resources, who are often pressured by their employer to "cut corners" to preserve a "bottom line" that sacrifices their integrity to corporate profit, is what the RFPT Programme was supposed to address when ASTTBC was first approached by the City of Vancouver back in 1996. ASTTBC’s latest Practice Guideline (they call it the SoP, that’s currently under review) represents a significant step in the WRONG DIRECTION, in my opinion. In point of fact, the combination of removing some key verbiage from the established 2008 Practice Guideline, AND eliminating the standardized report forms they once required their technicians to utilize, the level playing field they’ve been promising to deliver for as long as the Programme’s existed, is now a quagmire of confusing information and suggested links (some of which are completely irrelevant in Canada). Without the means for an AHJ to even IDENTIFY what that level field is supposed to look like, how can they hope to reconcile the proper testing of the building with the documentation that’s been provided by the people they’ve entrusted to perform it? ASTTBC’s latest “gem”, the RFPT Standards of Practice: Key questions for discussion at the Symposium May 17, 2017, was issued barely over a week before, likely in response to an email I sent Karen McDiarmid that had this to say about the SoP that’s currently being reviewed (and which is the subject of the Symposium):

I was, quite frankly (pun intended) taken aback, when I saw the list of questions posted to the ASTTBC website in advance of the all-day-symposium on May 17th. They aren’t what I expected a professional association with over 850 practicing members to be asking. Lets examine them in more detail, since it’s quite obvious I’m not going to be invited to this shindig: “Part 1 - Scope of Practice 1. To what extent is repairing, maintaining, adjusting or replacing fire protection equipment or systems included in the RFPT scope of practice?” ANSWER: According to the Definition of REPAIR in the proposed SoP, it’s supposed to be “zero”. It actually begs the question: Was this document, produced by a “stellar group of individuals and stakeholders”, further editorialized by someone at ASTTBC that’s so far out of touch with the industry, they’re probably not even living on this planet? Companies engaged in providing inspection, testing, and SERVICE to building life safety equipment and systems ARE ACTIVELY ENGAGED IN PROVIDING REPAIR, REPLACEMENT, AND MAINTENANCE of that equipment! Hello? Is anyone home? “Repair fix or mend (a thing suffering from damage or a fault). RFPT certification pertains to inspecting and testing. RFPT are not certified by ASTTBC to conduct repairs (for example, a part is replaced).” “... repairing, maintaining, adjusting, or replacing fire protection equipment or systems...” is a HUGE PART of a RFPTs daily activities, and provides the means for many of their more unscrupulous employers to actually make the rock-bottom price they quoted for the annual inspection, profitable. Go in as cheap as you can to get the job, then find as many deficiencies as you can so we can make some money. Sound familiar? Property managers have gotten a lot more savvy about this practice over the years, so companies that actively engage in the race to the lowest price have learned to find that sweet-spot of just enough deficiencies (sometimes carefully chosen ones that will make the previous company look “bad” or unprofessional), and those that can be exploited to take advantage of other labour-intensive “services” they provide (like charging a fee for slapping on a bogus fire extinguisher hydro-test label). More discussion would have resulted from these questions: What should we do about companies that engage in tactics that actually require our members to compromise their integrity and professional practice? Should ASTTBC set up an anonymous reporting system (like “Crimestoppers” only with a more appropriate catchy name)?

“2. Is manufacturers’ training a valid requirement for RFPT certification in endorsements such as Special Suppression Systems (SP) and Verification of Fire Alarms (VI)?” ANSWER: This is presented in TWO parts (because the question concerns two entirely different subjects (and disciplines/endorsements). i) Manufacturer’s training and certification is an absolute necessity when it comes to special suppression systems, for the very simple fact that technicians are actively engaged in INSTALLING, SERVICING, AND testing/inspecting them. As an INSTALLER, you have to follow very specific guidelines with respect to nozzle placement, calculating agent capacity, installing piping, considerations for ancillary devices (like UPS), coordinating with HVAC companies, etc. This also means you have to have ready ACCESS to manufacturer specified (and ULC Listed) compatible replacement parts. The installation of control equipment requires engaging a qualified electrician (if it’s a clean agent, or pre-action system), and interconnection to the building’s fire alarm system. If the system utilizes an electronic releasing panel, the authorized service technician may require training (and certification) in programming the proprietary software, performing final terminations in the control panel (in order to activate the manufacturer’s warranty), and preparing the system for the... ii) ... Verification of fire alarm systems and ancillary equipment. We’re going to provide one of the responses in our Verification FAQ here (for the sake of expedience and clarity): Who can verify a fire alarm system (in Canada)? What qualifications should they have? Can the installation company (or contractor) "sign off" on the Verification? AHJ's all across Canada have been deliberating over the definitive answer to this question for years. CAN/ULC-S537-13 states that the Verification must be carried out by an agency (or individual) acceptable to the Authority Having Jurisdiction, who can demonstrate they have the sufficient training or experience, and who is not the installing contractor or involved in the design of the fire alarm system. CFAA has published a position paper on the subject which attempts to establish the means by which an AHJ might formulate their own criteria, but it incorrectly suggests that only manufacturer trained technicians should perform Verifications “... where the system is of addressable design, software driven, or is a networked system...”. It is a sad fact that some manufacturer trained technicians are often ill prepared to actually identify even their own incorrectly installed fire alarm equipment (or the required wiring), let alone flag an installation as unacceptable which might jeopardize an established business relationship with the contractor (or the Registered Professional) under whose auspices they may have been contracted. It has been our experience that a good proportion of them are more concerned with ensuring the system is properly programmed (the software required has become even more complex partly as a result of the introduction of "mass notification" requirements and the firmware changes this has prompted). Manufacturer training should not automatically qualify a technician to perform a Verification! While the system software can undergo a form of programming verification, or program checking , the training that is provided by many manufacturers should not be confused with the required knowledge of the NBCC required Standards, the various Codes and local Bylaws that are the means by which a fire alarm system installation is confirmed as having been installed correctly in accordance with CAN/ULC-S524 and the design. The Standard for Verification of Fire Alarm Systems does not specifically identify anything that is manufacturer specific in the suitable formal training required of a qualified individual (in point of fact it would be ILLEGAL for any Canadian Standard to do so). “Any person who performs the verification of a fire alarm system should be familiar with this Standard and have received suitable formal training or sufficient experience acceptable to the authority having jurisdiction.” Many local authorities have adopted their own criteria when it comes to designating approved Verification agencies and acceptable individuals (we cover some of these on our TOOLS page). The City of Vancouver had, up until last year, taken the lead in this issue and defined not only the minimum acceptance criteria, but had actually listed individuals and organizations whom they deemed to be acceptable to provide commissioning and Verification of fire alarm systems in their Bulletin 2003-009-EL. They have since decided to offload the selection of the qualified Verifier, along with the acceptance of the properly formatted Appendix “C” documentation, to the Registered Professional that’s mandated to provide the NBCC required Schedule “CB” on a building project (this is further detailed in this April 2017 Tech-News article). Membership in a professional organization like CFAA or ASTTBC may provide some additional recognition, but until these organizations start supporting the individuals they certify, and provide the means to rigorously police their technician members, Verification inspections will continue to fall short of the Standard for the reasons we’ve already articulated here (as well as in several EDITORIALS and Tech-News Articles we’ve featured over the years). We've suggested several means to help an AHJ in determining the means to "vet" a verification test report. You can explore these options here and here. ULC has also issued a Standards Bulletin which may prove helpful as well. The Fire Technicians Network National Certification Programme (launched in March of 2017), provides a new benchmark for technician practice in Canada. Concurrent to the Programme’s launch is an expanded lab-based and online training initiative that features the ONLY dedicated Fire Alarm Verification Courses currently available. If your company has performed (or has been approved by the local jurisdictional authority to provide) a Verification and you have been contracted to provide the installation of the fire alarm equipment, you (and your company) are ineligible to verify the system. Even if you subcontract the physical installation work to another agency (who may have pulled the necessary permits), you are still viewed as the primary contractor. Some jurisdictions require the contractor to sign off in an "assisting capacity" to the actual verification agency. It is extremely important to recognize that an arms length relationship must be maintained between the individual (or company) performing the verification, the installing contractor and the system designer.

“3. Does endorsement in Commercial Kitchen Exhaust cleaning (CO) include inspection and testing of kitchen fire suppression systems?” ANSWER: MOST emphatically NO. It actually begs REPEATING a question we asked earlier: Was this document, produced by a “stellar group of individuals and stakeholders”, further editorialized by someone at ASTTBC that’s so far out of touch with the industry, they’re probably not even living on this planet? Can a company that provides commercial kitchen exhaust cleaning offer this additional service? Most emphatically YES, BUT ONLY IF they happen to employ an individual that’s been trained/certified by the suppression system manufacturer and (in a limited number of British Columbia jurisdictions) has the ASTTBC RFPT “SP”. Proof of manufacturer specific training must be provided in all other non-ASTTBC communities (and in the rest of Canada), with a couple of exceptions where you might see the requirement for technicians to be certified by the Fire Technicians Network as an LSST-K (or CLSS). Should an individual that’s testing/inspecting kitchen suppression systems REPORT deficient or non-conforming hood systems (including those with excessive grease build-up or where the cleaning is insufficient). Most emphatically, YES! Should they indicate non-conforming hoods on their service tags and reports? Again, most emphatically, YES!

“4. Is it necessary to distinguish between pre-engineered and custom-engineered special fire suppression systems if the certification criteria and competencies are identical?” ANSWER: What planet is the person that wrote this from again? Clearly not from ours as they don’t understand the difference between these two types of systems. YES, a technician with this endorsement must carry proof of having partaken in current manufacturer’s training on the specific system you are engaged to install, test, service, or repair. You must have access to the specific parts required (which can only be obtained by individuals that are working for companies that have been CERTIFIED through the manufacturer). Parts sourced from other suppliers (like on e-Bay, for example), will likely NOT conform to the manufacturer’s specifications and may render the entire system NON-COMPLIANT.

“5. Is it possible to describe certification criteria for endorsement in Verification of Alarm Systems (VI)? If yes, please provide criteria.” ANSWER: The individual that asked this is clearly living on Beta Epsilon IV. For those of you extra-terrestrials from other systems and/or galaxies, that actually RESIDE and WORK in the fire alarm service industry in Canada, here’s the answer: CAN/ULC-S537-13 - Standard for Verification of Fire Alarm Systems PREFACE “The requirements of this Standard contemplates that the verification procedure described herein will be conducted by an organization other that the installing contractor and designer, and that the verification will be carried out by qualified personnel in the employ of an organization acceptable to the authority having jurisdiction. (Refer to Appendix A, Qualified Personnel.)” 1 SCOPE “1.1 This Standard prescribes inspection and test procedures for the purpose of verifying that the fire alarm system is installed in conformance with the design and CAN/ULC-S524, Standard for Installation of Fire Alarm Systems, and performs all of its intended functions as designed.” Appendix A (Informative) - Qualified Personnel (Reference Preface) “A1 Any person who performs the verification of a fire alarm system should be familiar with this Standard and have received suitable formal training or sufficient experience acceptable to the authority having jurisdiction.” Do you need to familiar with the Canadian Electrical Code Sections 10 and 32? YES! Should you be reviewing some documentation specific to the installation (and the project) you’re Verifying before even setting foot on the premises? YES! Should you have sufficient knowledge of the system to effectively guide the individual doing the programming (or be able to identify if it’s been done correctly)? YES! Should you be completely familiar with the individual device’s installation requirements? YES! Should you be familiar with the Standard for Installation of Fire Alarm Systems (CAN/ULC-S524-06)? YES! Should you be familiar with the fire signal transmitters? YES! Should you have sufficient knowledge to perform a site evaluation and assist in (or draft) the Integrated Testing Plan when NBCC 2015 is finally accepted? Most emphatically - YES! More importantly, can someone with an ASTTBC “VI” endorsement successfully perform a fire alarm Verification to the Standard? Can someone with manufacturer’s training successfully perform a fire alarm Verification to the Standard? That depends on the individual you’ve engaged. Clearly, some cannot!! Mr. Justice Funt buried ASTTBC’s “VI” endorsement... and we can credit DeForest Kelly, the actor who played Dr. Leonard McCoy in the original Star Trek™ television series, with the final words on the subject: “It’s dead, Jim!”

“Part 2 - Reports (SoP Section 9, Pg. 15 & 16) 1. Who is responsible for submitting the fire protection service report to the building owner?” ANSWER: For those of you WORKING in the fire protection equipment service industry on THIS planet (and in one of the twenty-two British Columbia jurisdictions requiring RFPTs or acceptable alternative Certification), the ASTTBC Standard of Practice has ALWAYS identified the RFPT as the individual responsible for submitting information concerning deficiencies to the building owner and the AHJ. We, of course, understand WHY this is not done. And until a professional association steps up that will actually ADVOCATE for and SUPPORT technicians in ensuring they have the KNOWLEDGE, VIGILANCE, and INTEGRITY to... Oh, wait a minute... One just has! http://www.firetechs.net/services/services.asp

“2. What assurance does the RFPT have that the fire protection company will provide the inspection report to the building owner and make a copy available to the AHJ?” ANSWER: NONE! ZIP! NADA! It’s called CYA. It’s YOUR stamp! YOUR professional practice on the line. COVER YOUR ASSets!

“3. How many years should a fire protection company keep reports?” ANSWER: Check with your corporate Liability Insurance Carrier. Most will suggest seven years. Some go as high as ten. An SoP could make the recommendation for the higher number, but then, the SoP only applies to ASTTBC RFPTs, and NOT their employers.

“4. Shoud RFPTs keep their own records of work if working for a fire protection company?” ANSWER: From the last paragraph of my email to Karen McDiarmid - Keep in mind that even though the SoP clearly states the RFPT’s responsibilities in reporting non-compliant, non-functional fire safety equipment, the ability for them to DOCUMENT and maintain records of the service could well contravene an employer’s Code of Conduct and/or entail accessing privileged, confidential company information. Further discussion will be necessary to formulate a method which protects both the interests of the employer as well as the RFPT who may have to respond to a complaint down the road.

Let’s hope that the May 17th, 2017 Symposium will result in some more positive and workable content for the SoP, and for the RFPTs that are going to have to follow it. Oh, and the extra-terrestrial that wrote this questionnaire, should really be encouraged to apply for a job in a place called “Washington, DC”, where asking really soft questions actually qualifies you for an amazing job with another equally professional, alternative reality based association called “FOX News”.

You can read more concerning technician practices, testing methods, etc. by clicking on: Check out our EXTINGUISHER FAQ page, for more information! Testing forms and documentation can be found at:

AHJ Training Courses are being offered by two (2) Canadian national associations:

Canadian Fire Alarm Technician Certification:

Certified Fire Extinguisher Requalifiers (National):

Fire Protection Technicians (British Columbia only):

We’ve tabulated the expense and charted the training/endorsements which the three Canadian training and Certification programs provide at https://traininginstitute.firetechs.net/Overview/tech_training_overview.asp.

INTERESTED IN COMMENTING ON THIS ARTICLE? QUESTIONS? GOT A STORY? SOMETHING OF INTEREST AND/OR NOTE-WORTHY?

|

||||||||||||||||||||||||||||||||||||||||

The Fire Technicians Network

+1 (888) 340-3473

“We are not a professional union, but together, we are a union of professionals!”

What we’re all about!

We are not affiliated with ASTTBC, CFAA, CANASA, NFPA, NAFED, or NICET (although we encourage you to explore and objectively evaluate the benefits associated with supporting their individual efforts). Membership in the Fire Technicians Network is entirely voluntary. Are you up to the challenge of demonstrating your commitment to public safety and the highest standard of professional practice?

Copyright © 2007 - 2020 The Fire Technicians Network. All Rights Reserved